Nickel Titanium (NiTi) is a Shape Memory Alloy (SMA), which means that once deformed, it has the ability to return to its pre-deformed shape when heated. In wire form, this material can be used as a very strong, and silent, linear actuator. However, its achievable strain is only around 4-6%. To achieve a large displacement, one needs a long length of wire, which demands a large housing. This greatly restricts the range of practical applications of this actuator.

My goal in researching this material was to address this technical challenge. Previous research conducted on SMA wire had investigated spooling as a solution, determining friction and bending stress in the wire to be the greatest sources of loss in performance. I decided to investigate the wire’s performance when spooled around low-friction bearings instead of stationary mandrels.

While there was still some loss in strain when comparing this spooling method to using a straight length of wire, the losses were minimal. Hopefully, this method will be used in the future to allow for compact, silently actuated machines, such as prosthetic devices.

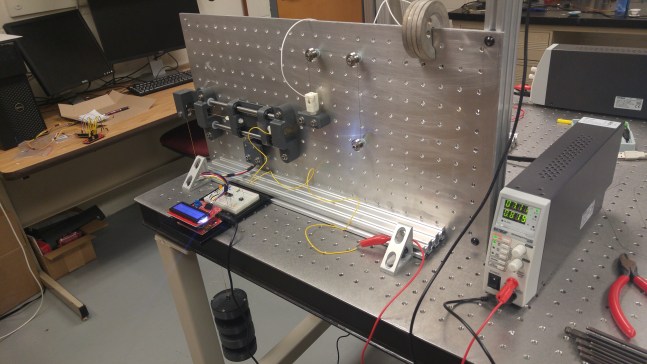

Shown is a picture of the apparatus used to test the displacement in different configurations of the wire.